Product Description

Price is for EA.

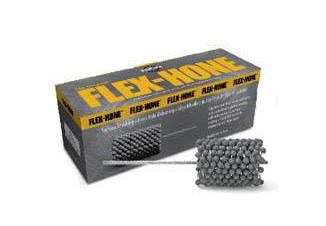

- Flex-Hone Tool

- Type Heavy Duty

- Capacity 8 To 7-1/2 Inch (Bore)

- Size 8 Inch Diameter X 17-1/2 Inch Length

- Applicable Standard Iso 9001

- Abrasive Type Silicon Carbide

- Grit Size 180

- End Marking Color Cardinal Red

- Application Automotive, Military, Aerospace, Marine, General Industrial, Manufacturing, Oil And Gas, Firearm, Musical Instrument, Fluid Power, Hydraulic, Aluminum Extrusion, Earth Moving Equipment

Features / Benefits

- SURFACE FINISHING - The Flex-Hone Tool is available in a variety of abrasive types and grit selections to provide the optimum surface finish on any base material

- The Flex-Hone is commonly used to reduce Ra, Rk and Rpk values while maintaining Rvk and Vo volume for oil retention

- Using the Flex-Hone Tool for surface finishing allows the sizing tools to do their jobs quickly and accurately without fighting surface finish

- The Flex-Hone is also used in adhesive bonding applications where a rougher surface is desired for bonding integrity

- DEBURRING - Debarring of cross drilled holes is an expensive, time consuming operation. The Flex-Hone Tool can be used to remove burrs from cross drilled holes leaving a clean, radiused intersection

- Because of its unique construction, the Flex-Hone can be used online in machine tool applications or offline as a secondary operation

- The tool is self-cantering and self-aligning to the bore so elaborate, rigid set-ups are not required

- It is advisable to use the tool in the main bore into which the cross holes break

- Best results are obtained by rotating and stroking the tool a few strokes in a clockwise direction, removing the tool from the part, reversing the spindle and then rotating and stroking the tool in a counter clockwise direction for a few more strokes

- This forward and reverse rotation creates a more symmetrical debarring pattern

- PLATEAU FINISHING - Brush Research pioneered the concept of a plateau finish and is a strong proponent of the benefits of a cross hatch, plateaued finish

- The concept involves removing the peaks produced by prior machining operations and creating a substantially flat or plateau finish

- A plateau finish created by the elimination of peaks allows rings and seals to seat without damaging their edges

- The cross hatch pattern will aid in lubrication control and retention, reduce seepage in hydraulic and pneumatic applications and promote longer seal life

Part Number: GBD80018

UNSPSC: 31191500

| PROP 65 WARNING | Yes |

| Catalog Pages(s) | |

| Other Document 1 | |

Add custom text to promote products, specials or offers

Comment